The TII Group site in Champs-sur-Yonne is the sales centre for TII SCHEUERLE transport solutions and the centre of excellence for servicing existing vehicles in fleets of French customers, including the industrial vehicles of TII KAMAG and the TII brand NICOLAS. The site is also dedicated to retrofitting existing vehicles and supplying spare parts to French customers. With this clear mission, innovative products, comprehensive knowledge of the needs of French customers and long-standing contact with them, the industry experts at the TII Group will further expand their market position in France. The TII Group will present this strategy and selected products and services to customers in Champssur-Yonne in mid-September. A semi-modular EuroCompact lowbed trailer and a SCHEUERLE SPMT PowerHoss testify to the performance of the product range on site.

For more than 150 years, the industry experts at TII have been passionate about manufacturing technologically leading transport and manoeuvring solutions for transport and industrial logistics. To this day, the needs of the customers TII SCHEUERLE and TII KAMAG continue to drive them to offer the best possible solution for their business activities. With their exceptional industry experience and expertise, the industry experts at the TII Group enable their customers to work together to solve their complex problems, regardless of the size and scope of the customer project. The mission of TII is to meet the needs of all transport challenges reliably and in partnership. After all, TII customers don’t just buy a product; they buy a partnership that lasts throughout the vehicle’s lifetime and beyond.

A pronounced customer focus is a core element of TII. The traditional group of companies, which has been owned by the Otto Rettenmaier family for more than 35 years, operates with a view to the long term. Consistency, passion for the job and a high degree of reliability are the priorities of TII. The extraordinary knowhow of the TII industry specialists TII SCHEUERLE and TII KAMAG, as well as their innovative strength, comes from decades of work.

Industry experts for on and off-road heavy goods logistics and in-house transport

Thanks to the modernised brand architecture within the TII Group, all customers are able to clearly allocate their industries and areas of application to the two industry specialists. TII SCHEUERLE is the specialist in heavy goods transport solutions on and off the road. These include solutions for the construction and energy industries, as well as for the aerospace, shipping and other industrial sectors. TII KAMAG, in turn, develops in-house transport solutions. These include vehicles for yard logistics and metallurgy as well as all vehicles specially developed for each application.

TII experts in Champs-sur-Yonne know the needs of French customers

The specialists at the TII Group site in Champs-sur-Yonne, around 1.5 hours south of Paris by car, have special expertise in meeting the needs of customers in France. Their know-how encompasses the distribution of transport solutions from TII SCHEUERLE in France, including servicing these and the industrial vehicles of TII KAMAG, while the logistics vehicles of TII KAMAG will continue to be managed by the longstanding and dependable partner Aprolis. In addition to classic repair and maintenance, the services offered by the Champs-sur-Yonne site include retrofitting, i.e. the comprehensive modernisation of existing vehicles. By replacing the electrical, electronic and hydraulic systems in particular, tried-and-tested vehicles can be given new functions. It is even possible to carry out extensive modifications – such as those that involve work on the chassis.

Thanks to these measures, the transport solutions, which often remain in a fleet for many years due to their enormous value, remain state-of-the-art and are equipped for any challenge. This makes retrofitting a particularly cost-effective measure for fleets to respond flexibly to the changing needs of their customers.

High availability of spare parts and short delivery times

The Champs-sur-Yonne site also supplies all customers in France with spare parts via the fastest possible route, for which the company maintains ample storage capacity at its headquarters. Other services provided by the experts at the TII site in France include load case planning with SALSA + and training in the use of the simulation software, as well as equipping the transport solutions of TII SCHEUERLE with the fleet management system SCHEUERLE Connect. The telematics system delivers vehicle data in real time, making it possible to efficiently plan downtimes. In addition, SCHEUERLE Connect prevents unplanned breakdowns with the help of condition-based maintenance, which optimises the operating costs of each vehicle.

Retrofit project carried out for Airbus in Champs-sur-Yonne

In order to guarantee a comprehensive range of services, the 3,500-square-metre site features a sandblasting facility, a paint shop and a 1,400-square-metre service facility in addition to the administration buildings. Repair and retrofit orders have already been completed there successfully. Amongst other things, the service experts overhauled six self-propelled transport vehicles from the fleet of aircraft manufacturer Airbus and modernised their electronics and powerpack drive units.

Aymeric Pasquier is in charge of retrofitting and services at the TII site. Jean-Louis Jonet is in charge of sales. A team of 25 sales and service experts supports the two managing directors. All employees have many years of industry experience and, on average, have worked for the TII Group for more than two decades.

A clear remit and special expertise strengthen the growth trajectory

The clear remit of the site within the TII Group, the special know-how and the close contact of the TII employees with French customers form the foundation for the further growth of the group in France. This is because the demand for modernisation and retrofitting of existing vehicles is constantly increasing. At the same time, retrofitting, maintenance and servicing of high-quality transport solutions like those produced by the TII Group’s industry experts require experts who know every detail of the vehicles and their customers’ needs inside out.

TII SCHEUERLE: the specialist in heavy goods transport solutions on and off the road

TII SCHEUERLE’s portfolio ranges from semi-modular towed vehicles with payloads from 37 tonnes to modular, self-propelled transport and manoeuvring solutions that theoretically allow unlimited payloads and can be precisely configured for each application. In addition, there are special applications for the transport of particularly demanding loads, including transport solutions for wind turbine segments and rotor blades and ship section transporters.

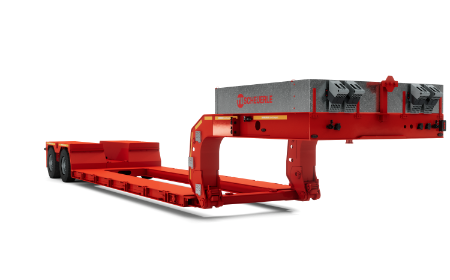

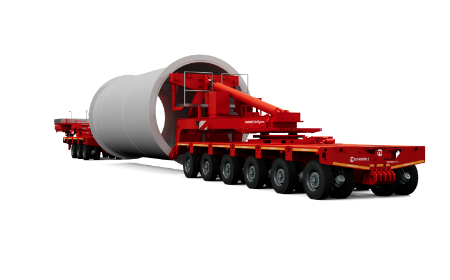

To demonstrate the power and versatility of its product range, TII SCHEUERLE will be showcasing a semimodular EuroCompact U9 lowbed trailer with 0+3 axle configuration and a SCHEUERLE SPMT PowerHoss 85 with two axles and an 85-tonne payload at the Champs-sur-Yonne site.

EuroCompact lowbed trailer: high payload, low unladen weight

The weight-optimised EuroCompact models offer an outstanding payload in the segment, extremely easy operation and low operating costs. The semi-modular EuroCompact U7 series has a particularly high payload. It comprises weight and length-optimised semi-trailers with up to ten axles, spread over a front and a rear chassis with four or six axles. Thanks to their versatile combination options, they are suitable for transporting up to 106 tonnes. The SmartAxle add-on bogie offers even more flexibility. SCHEUERLE rounds off the range for road transport with the two and three-axle configurations of the U9 series, which have a particularly favourable ratio of payload to unladen weight and allow payloads of up to 37 or 48 tonnes.

In addition to the payload, the focus of all EuroCompact models is on the most compact design in the segment and high cost-effectiveness. Both the two and three-axle versions offer an easy-to-extend telescopic plate bridge and can achieve loading lengths of up to 12,270 or 12,610 millimetres respectively. The EuroCompact models are also intuitive to operate. The clever coupling system plays a key role in this. With its help, the gooseneck can be easily disconnected and reattached even in the field, not to mention the large stroke of 650 millimetres in the swing axle chassis. Combined with a large steering angle, the articulated truck combination can easily pass through tight spaces. Due to the favourable ratio of total train length to load length and their high manoeuvrability, EuroCompact trailers are subject to fewer requirements during transport. This simplifies approval processes and significantly speeds up workflows during deployment, resulting in lower operating costs and significantly improved vehicle efficiency.

The semi-modular lowbed trailers from the EuroCompact series are used in the construction and forwarding industries to transport containers, construction machinery, as well as stone crushers, transformers and other heavy equipment. They are available in special industry configurations and are highly versatile thanksn to the extensive range of accessories. In addition, development at TII SCHEUERLE is progressing steadily. Even more practical additions to the series will gradually open up additional benefits for customers.

SPMT PowerHoss: the all-rounder in intralogistics

The SPMT PowerHoss is the all-rounder in intralogistics and suitable for small and large loads of all kinds. Thanks to its compact design with integrated engine, the transport vehicle is ready for use immediately in line with the plug-and-play principle. The PowerHoss series comprises vehicles with a choice of two, four or six axle lines. Payloads of up to 85, 175 or 330 tonnes per module are possible. In addition, SCHEUERLE SPMT PowerHoss modules can be operated either mechanically or electronically in an open compound system, according to the plug-and-play principle, in order to meet even higher payload requirements. A combination of SPMT PowerHoss 330, each with six axle lines, is capable of moving loads with a unit weight of up to 1,320 tonnes. The installation assistant and transfer unit is easy to operate and can be used both offroad and in-house. Thanks to the container width of 2,430 millimetres, the SPMT modules can be transported to the most remote locations in the world in the shortest possible time and as economically as possible using a standard container (flat rack).

Revolution in 1983: the SPMT changes industrial processes

All SPMT PowerHoss models offer the advantages of conventional SPMT vehicles, namely the robust design of the swing axle chassis with a stroke of 700 millimetres and the electronic multi-way steering with all known steering programs, which allows for highly precise navigation of the goods. They are also based on the technology of the SPMT series, which has been tried and tested for four decades. In 1983, the vehicle manufacturer known as Fahrzeugfabrik SCHEUERLE, now known as TII SCHEUERLE, revolutionised heavy transport logistics. To this day, the hydraulically supported swing axle and electronic multi-way steering, both innovations from TII SCHEUERLE, form the technical basis of the SCHEUERLE SPMT and the SCHEUERLE SPMT PowerHoss. Due to the wide range of potential mechanical and electronic combinations of the individual modules, transport with theoretically unlimited payloads has been possible ever since. The launch of the SPMT made it possible to set up advanced production processes for modular industrial and conveyor system construction, not to mention infrastructure projects, and the efficiency of small to large transports increased significantly worldwide.

A global market leader and world record holder: SCHEUERLE SPMT axle lines are available globally

Today, the various SPMT transport modules, including SCHEUERLE SPMT InterCombi SPE, SPMT K24 and K25 SPE, are used to transport goods as diverse as valuable luxury yachts, industrial systems weighing thousands of tonnes, components of gigantic mining vehicles and offshore wind turbines as well as complete hotels and monasteries. Today, SPMTs from TII SCHEUERLE represent the largest number of SPMT axle lines on the market worldwide. This enables customers around the world to rent SCHEUERLE SPMT axle lines or use partners with compatible modules to transport the heaviest of loads. And with success: SPMTs from TII SCHEUERLE hold the current world record for the heaviest transport. Most recently, Mammoet transported a load of 20,300 tonnes with an SPMT from SCHEUERLE.