Hyundai Heavy Industries has once again purchased ShipyardTransporters from TII SCHEUERLE. In future, five additional ship section lift transporters will be used at the world's largest shipyard. Haulage specialists, Spedition Kübler, recently transported the first two vehicles from the plant in Pfedelbach to the Heilbronn inland port facility. The designated route was kept exclusively on country roads. Great skill was required at roundabouts as well as through towns and villages. Often, there were only a few centimetres of space between the eight metre wide load and house and tunnel walls.

Centimetre by centimetre, the heavy load made its way through the narrow streets of Hohenlohe. The two vehicle combinations, almost 40 metres long in total, transported one SCHEUERLE ShipyardTransporter in each case Each of these vehicles was eight metres wide. There has never been a special transport assignment of this size that had only used country roads throughout. In some places along the route between Pfedelbach and the Heilbronn harbour things became extremely tight. Often, only a hand's breadth separated the two 25 metre long, 1.9 metre high and 151 t colossal transport from numerous house walls. Hence, in the main road through the town of Bitzfeld, the width between the houses is just 8.22 metres. However, there was not much more space available along other parts of the route either. The Michelfeld-Erlin based Spedition Kübler team proved once again that they are the specialists for handling such tasks. In spite of the immense width of the transport, they could comfortably deal with any bottleneck.

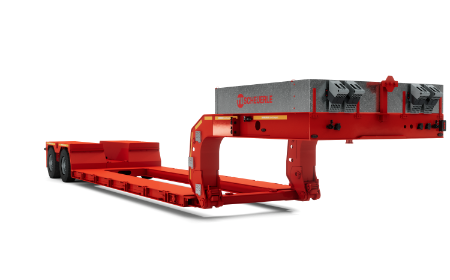

A case for the SCHEUERLE InterCombi: robust, manoeuvrable axle lines are required on rural roads

The SCHEUERLE InterCombi axle lines also contributed to ensuring the success of the assignment. Kübler used 18 of these along with one four-axle tractor unit per ship section lift transporter in order to take the transporters the first 30 kilometres on the long journey to the customer. The InterCombi axle lines are likewise manufactured by TII SCHEUERLE, the industry expert for heavy transport on paved roads as well as off-road, a subsidiary of the TII Group. The series consists of modular platform vehicles with a width of three metres. They are flexible all-rounders that are suitable for handling a wide range of transports. Thanks to the low platform height and wide support base, even exceptionally wide loads such as ship section lift transporters or those with a high centre of gravity such as extremely heavy construction machinery and mining equipment, wind power plant components, transformers or bridge elements can be safely and reliably transported.

Congested motorways: convoy reached its destination only by using country roads

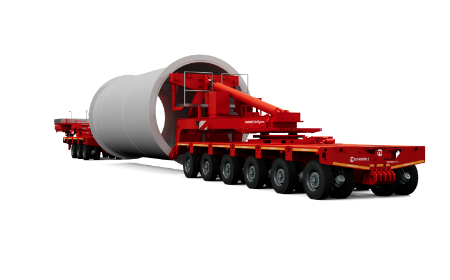

With a maximum steering angle of +/- 60 degrees, the InterCombi platform vehicles are manoeuvrable enough to transport the wide loads through tight bends as well as negotiating roundabouts and travelling through restricted spaces in town and village centres along the route. From the SCHEUERLE production plant in Pfedelbach, the convoy only proceeded on country roads as all motorway bridges that had to be crossed could only take a lower load and transporting this weight on the motorways is not possible. Traffic signs and traffic lights had to be temporarily removed while sections of a construction site were also moved out of the way for the convoy. Several times the transporters had to use the lane of oncoming traffic or take the route through the middle of a specially covered roundabout. Metal drive-over sheets and curbstone wedges protected green areas and curbs respectively. However, such measures are routine for the Kübler team. After 7.5 hours, the transport arrived safely at the Heilbronn harbour facility.

Tried and tested: Hyundai Heavy Industries has numerous SCHEUERLE ShipyardTransporters in use

From Heilbronn, the barge continued on to the port of Antwerp where the two transporters were transferred to a seagoing vessel by the TII SCHEUERLE service team. Their final destination: South Korea. In future, the two ShipyardTransporters will be used by the South Korean company, Hyundai Heavy Industries, in the world´s largest shipyard. A number of TII SCHEUERLE ship section lift transporters have been providing valuable service there for decades. In total, the new order from Hyundai Heavy Industries includes five SCHEUERLE ShipyardTransporters. Each of these provides a payload of 800 tonnes in order to move ship sections and other heavy shipbuilding components. Up to six of these giant vehicles can be coupled together to safely manoeuvre even the largest ship sections with a total weight of up to 5,000 tonnes.

Major order: three more ship section lift transporters on their way to South Korea in 2024

Two additional SCHEUERLE ShipyardTransporters will make the long journey to South Korea at the beginning of next year while the fifth vehicle will also be delivered next year. The professional team at Kübler will then demonstrate their skills once again and transport the ship section lift transporters safely to Heilbronn.