Companies in the metallurgy industry require transport solutions to support them in optimising their sustainability and the economic efficiency of their logistics fleet. At the leading fair, Metec 2023, TII KAMAG presented a special vehicle, the KAMAG industrial lift transporter, which shows that these demands can be met. Customers especially lauded the modern design of the newly-designed cabin with its excellent views and the ergonomically designed driver’s cab.

The metal industry is facing big challenges. It needs to continuously meet the growing environmental protection demands, which include the decarbonisation of internal transport logistics, as well the growing need for efficiency. At the leading international fair for metalwork technology in Dusseldorf, Metec 2023, TII KAMAG, the industry expert for internal transport within the TII Group, demonstrated the manufacturer from Ulm’s transport solutions to equip the metallurgy industry for the future.

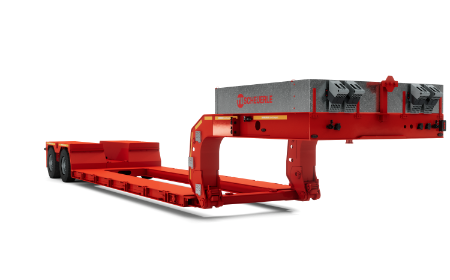

Representative of the complete product range, TII KAMAG displayed the completely modern cab of the industry hub transporter, the KAMAG IHT, a specialised vehicle used to transport semifinished steel products such as sheets, slabs, coils and beams or even junk palettes and pails. The expert visitors praised the modernised cabin and the large glass surfaces which give a wide, direct field of vision around the vehicle which, in turn, improves workplace safety. This is also improved by the stair-like access, from which the driver can access their workplace. The modern, ergonomically-designed aspects of the KAMAG IHT’s cab also won praise. Important benefits found in the new cabin include the ease of control from the joystick and the central display connected to the driver seat which turns alongside the seat when turning. This ensures that key information is never out of the driver’s sight.

On top of that, the serviceability and low maintenance times for the metalwork fleet play a key role. In the face of high cost pressures, they allow for continued lower vehicle operating costs. And here is yet another reason to choose the new KAMAG IHT. It’s engine is even more accessible through a large hatch at the side of the vehicle when maintenance and service is required. This reduces downtimes, improves availability and leads to lower operating costs. Data obtained from the vehicle also plays an important role in economic efficiency. The KAMAG IHT comes with a remote maintenance option, giving experts from KAMAG the possibility to access the vehicle directly from any location if there is an issue. This means they are able to minimise, or even completely avoid, any unplanned downtimes.

The need for ever more sustainability in the transport industry is also being met by TII KAMAG’s engines, which are able to close off the hydraulic oil’s cooling system when needed. This can save up to 15% of fuel during transport.

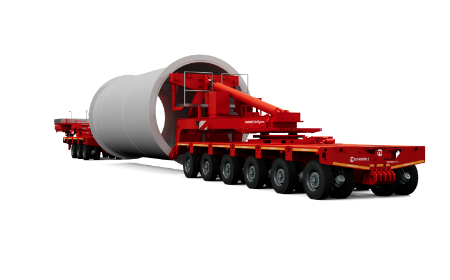

The KAMAG SlagPotCarrier (SPC) was also in high demand. The Slag Pot Carrier is a bestseller in the metallurgy industry and like the KAMAG IHT, also benefits from remote maintenance and efficient engine technology. A particular design feature of the KAMAG SPC is the exhaust gas collection tank. By preventing the exhaust gases from entering the surrounding atmosphere, it can also protect the metalworkers’ health.

“We we’re very happy with the interest shown. Both current and new customers showed definite interest in placing orders and were impressed with the excellent industry know-how of TII KAMAG’s experts, thanks to which we could show we are able meet their demands,” said Reiner Lohrmann, TII KAMAG Technical Division Manager for Industry and Special Projects.