Harsco Environmental has added another vehicle to its fleet of KAMAG SPC slag pot carriers at its Brescia facility. Once again, Harsco Environmental has decided in favour of a special vehicle from TII KAMAG primarily because of the positive experience gained through the use of existing vehicles as well as the option of remote diagnosis and maintenance.

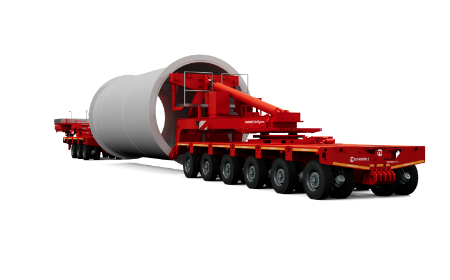

Since 2013, Harsco Environmental, a specialist in waste disposal services in steel mills, has been using a KAMAG SPC (Slag Pot Carrier) at a steel manufacturer's plant in Brescia, Italy, to transport molten slag from the blast furnace to the tipping pits. A demanding task under extreme conditions such as heat and sharp-edged, dusty and heavy transport materials that require particularly robust and powerful vehicles. The experience at the Brescia site and other Harsco Environmental operational facilities in Europe have shown that the KAMAG SPC comfortably meets the requirements. The environmental service provider is also impressed by the quality of the KAMAG scrap basket transporters which the company also uses in Brescia.

Remote diagnosis and maintenance ensure minimal downtimes

For this reason, Harsco Environmental has now acquired a fourth slag pot carrier from TII KAMAG through the company´s Italian dealer, Fratelli Ursini. “We appreciate the ease of handling and reliability of the KAMAG transporters,” explained Stefano Balducci, Asset and Maintenance Manager at Harsco Environmental. “One thing more in the favour of TII KAMAG is that the manufacturer has always adapted its transport solutions to fully comply with our special requirements at the Brescia location,” said Stefano Balducci. Another plus point for TII KAMAG is the option of remote maintenance. “This is a requirement that we made clear from the start. “Remote diagnosis guarantees our service technicians of receiving a precise error analysis when required and, in connection with remote maintenance, ensures the shortest possible downtimes,” according to Daniele Rizi, workshop manager at Harsco Environmental.

KAMAG is a full-range supplier for the metal industry

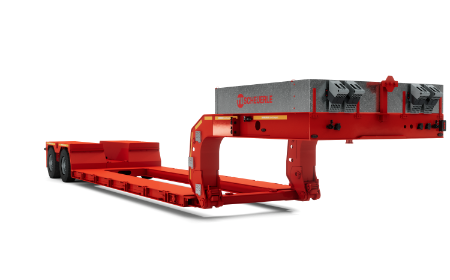

TII KAMAG provides the right solutions for all transport tasks in the metal industry. The industry expert for in-plant transportation assignments, a subsidiary of the TII Group, offers transport solutions for scrap management as well as for molten steel, slag and semi-finished product transports. The range of slag pot carriers includes vehicles in platform and U-frame designed constructions. TII KAMAG produces the platform slag pot carrier with two or three axles and provides payloads of 40 to 120 tonnes. The range of vehicles for the metallurgy sector also includes ladle and slab carriers, industrial lift transporters and scrap basket transporters as well as set-down skip loaders, articulated vehicles and coil transporters.