In 1983, Scheuerle Fahrzeugfabrik – now known as TII SCHEUERLE – developed and launched a market-leading technology that has shaped the heavy-transport industry to this day: the Self-Propelled Modular Transporter (SPMT). Due to the diverse combination possibilities of the individual modules, transport undertakings with theoretically unlimited payloads have been possible ever since. This has revolutionised the possibilities of the industry and significantly increased the efficiency of small to large transport undertakings worldwide. Even the name ‘SPMT’, which is generally used today, originally came from TII SCHEUERLE.

Tempo, Tesa, Zeppelin, SPMT – four different products that all have one thing in common: their name is synonymous with an entire product category. When an innovation catches on, its level of recognition increases strongly and it achieves a high market share. This is just as true of tissues, adhesive tape and airships as it is of the self-propelled modular transporter (SPMT), which has been moving the world in the truest sense of the word ever since. Several 10,000 SCHEUERLE SPMT axle lines are now in use worldwide, and the SCHEUERLE SPMT has become the global standard. This year, the revolutionary manoeuvring and transport solution is celebrating its 40th birthday.

A revolutionary transport solution makes history

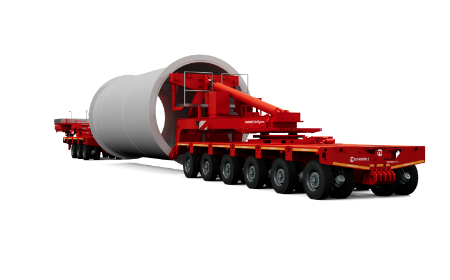

Constant innovation has been part of TII SCHEUERLE’s DNA right from the outset. ‘Our customers’ needs for func-tionality, cost-effectiveness, safety and efficiency are our incentive, because TII SCHEUERLE wants to enable all cus-tomers to achieve top performance, regardless of the size of their company,’ explains Dr Gerald Karch, CEO of the TII Group. This is what happened in 1983, when the idea of the modular platform transporter with a container width of 2,430 millimetres was born from the needs of long-time customer Mammoet. This dimension ensures that the transport solution can be moved with the help of a standard container (flat rack) in the shortest possible time and as economically as possible, even to the most remote locations worldwide, and that the modules can be transported on land on motorways. Today, TII customers use the various SCHEUERLE SPMT series – which also include SCHEUERLE SPMT InterCombi SPE, SCHEUERLE SPMT K24 and SCHEUERLE K25 SPE – to move a variety of goods such as valuable luxury yachts, industrial plants weighing thousands of tonnes, components of gigantic mining vehicles and offshore wind turbines, as well as complete hotels and historical cultural assets.

The modularity and combinability of the axle lines allow the platform trucks to be flexibly adapted to the respective payload requirements. One or more Power Pack Units (PPUs), which can be coupled to the SCHEUERLE SPMT mod-ules as required, generate the energy for the hydrostatic travel drive, steering and lifting. The technical basis of the SCHEUERLE SPMT was then, as now, the hydraulically supported oscillating axle, which Willy Scheuerle invented as early as 1956, as well as the electronic multidirectional steering for heavy transporters in 1972, also an innovation by Willy Scheuerle.

Unlimited combination possibilities and a theoretically unlimited payload

The introduction of the SCHEUERLE SPMT opened up new possibilities for the construction of large and complex indus-trial plants. The wide range of options for coupling SCHEUERLE SPMT axle lines mechanically or electronically in open formation allowed a theoretically unlimited payload for the first time. The industry recognised the opportunity to realign the production of industrial and conveyor systems, factory modules and other extremely heavy components. Instead of individual blocks weighing a maximum of 300 tonnes, they could now manufacture several 1,000-tonne plant modules and transport them to the place of use. As a result, SCHEUERLE SPMTs enabled the industry to manu-facture large-scale plants much more economically and transport them more efficiently.

SCHEUERLE SPMT – worldwide availability for superlative transports

Today, SPMTs from TII SCHEUERLE represent the largest number of SPMT axle lines on the market worldwide. The consistency of the basic technical principle is another key success factor of the SCHEUERLE SPMT. This is because the axle lines of the different generations are compatible with each other, so new axle lines can be easily combined with existing modules. This enables customers worldwide to rent SCHEUERLE SPMT axle lines or use cooperation partners with compatible modules to carry out demanding heavy-transport operations. SPMTs from TII SCHEUERLE also hold the current world record for the heaviest transport. Most recently, TII SCHEUERLE customer Mammoet transported a load of 20,300 tonnes using SPMTs from SCHEUERLE.

Continuous further development

The development of the SPMT series continues to progress at TII. SPMT modules are available with three-, four-, five-, six- or eight-axle lines and also allow axle loads of up to 60 tonnes. Special versions are available as well such as the SPMT SL (split type), which can be split in the middle. If two vehicles are too wide for the job and one is too nar-row, the SCHEUERLE SPMT SL can solve the problem: a centre section connects them to form a so-called three-file combination with 1.5 times the width. Another variant, for instance, is the SCHEUERLE SPMT with Arctic Package for use in extremely cold areas and temperatures down to minus 40 degrees Celsius.

SCHEUERLE Connect telematics opens up additional possibilities and saves operating costs

TII SCHEUERLE has just introduced another innovation in the segment with the SCHEUERLE Connect telematics solu-tion. The new telematics significantly simplifies fleet and service management and improves economic efficiency as well as transparency in the fleet. SCHEUERLE SPMT fleet operators benefit from digital services such as remote diag-nostics, smart services, intelligent maintenance management and condition monitoring. As a result, operations and service times of the TII transport solutions can be better planned, and the uptime of the transport and manoeuvring solutions increases significantly while operating costs are in turn reduced. This is because unplanned downtime and consequential damage can be largely avoided with the help of SCHEUERLE Connect. However, not only new vehicles are available with telematics. It is also possible to retrofit SPMT existing fleets with SCHEUERLE Connect.