Heavy-load specialist P. Adams acquires three rotor blade transport systems (RBTS) from TII SCHEUERLE for transporting the longest rotor blades on the market safely and efficiently. The forwarding company, which specialises in wind turbines, mastered the first practical application with 83-metre-long blades with flying colours. Company boss Stephan Adams was highly satisfied and praised the operability, functionality and driving characteristics of the innovative award-winning trailer combination.

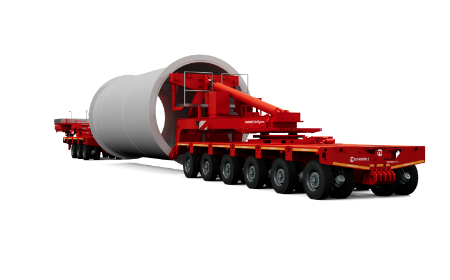

The transport of each rotor blade took two full nights. A total of 24 rotor blades had to be transported along the approximately 170-kilometre route from the port city of Uddevalla in western Sweden, where the wind turbine components were handled, to Knöstad, which is located further north-east. A leading European wind farm developer needed the 24 rotor blades to set up eight wind turbines there. The transport involved using the RBTS from TII SCHEUERLE and was mainly carried out on Swedish country roads. In the process, the convoy had to manoeuvre around numerous bends and, at the end of the transport on the construction site, also had to negotiate steep gradients and unpaved roads. The particular challenge of this task was transporting goods that were 83 metres long. These rotor blades are amongst the longest versions available on the market. The loaded tractor-trailer combination was 96 metres long and weighed around 65 tonnes, whereby the load itself was in the region of 30 tonnes. Precisely because of the length of the vehicle combination, this was a task for real professionals such as those who work at the Luxembourg-based company Transpalux, which belongs to the P. Adams Group. ‘Although the bends were widened, our operators still had to constantly adjust the steering,’ reports Stephan Adams, managing director of the P. Adams Group.

‘For blade lengths of more than 75 metres, there is no alternative to a trailer unit combination’

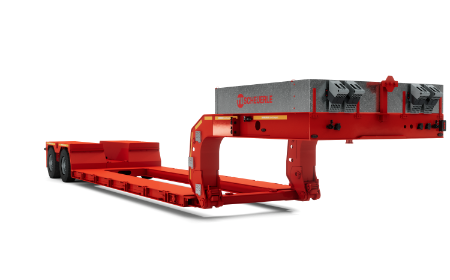

‘Transport equipment such as the RBTS from TII SCHEUERLE is the only alternative for transporting rotor blades with lengths of more than 75 metres over long transport routes. After the first major deployment, we are very satisfied with the jeep-dolly trailer combination,’ praises Stephan Adams. The SCHEUERLE RBTS consists of a two-axle jeep dolly together with a free-turning device and a four-axle trailing unit. It is also possible to mount the free-turning device directly on the truck tractor, but this means that a four-axle or five-axle semi-trailer tractor is required due to the high fifth-wheel load while Transpalux uses three-axle vehicles.

Easy and quick installation of the wind turbine blade

Assembly of the wind blade is carried out according to the plug-and-play principle. With the help of a special lifting device, the wing root is comfortably picked up from the ground. The quick coupling solution is comprised of the free-turning device along with the root adapter and a root frame that is connected to the blade root. This frame can then be secured to the free-turning device in next to no time with the help of the adapter. A clamping device on the trailer unit is used to fix the tip of the rotor blade into position. It can be adapted to accommodate rotor blades from other manufacturers.

Driver and operator benefit from the easy handling of the SCHEUERLE RBTS

The deployment marked a first for the RBTS at P. Adams. All three RBTS trailer combinations were used in Sweden. ‘Prior to this transport assignment, our drivers had only worked with telescopic semi-trailers and up until now we had only had the opportunity to try out the RBTS in the form of a test load. However, in the end this wasn’t a problem for our drivers. They quickly became familiar with the equipment functions. It all worked out extremely well,’ says Adams. According to the company boss, this was also due to the comparatively simple handling of the RBTS. ‘Our drivers mastered it in a very short time,’ he reports.

‘Consultation and service speak for TII SCHEUERLE’

The primary focus of the Swedish special-goods logistics company’s activities is on the transport of components for the wind energy industry. ‘In the case of the RBTS, we made a conscious decision to go with TII SCHEUERLE. After looking at offers from various vehicle manufacturers, we felt that we were in the best hands with them,’ explains Stephan Adams. According to Adams, TII SCHEUERLE had the greatest understanding of the special requirements involved. This included, for example, the request for a safety-enhancing functionality. In order to keep the centre of gravity of the load in the longitudinal axis of the vehicle as much as possible, Adams required a lateral compensation feature in order to shift the load to the left or right depending on the situation. A requirement that TII SCHEUERLE naturally was able to successfully implement.

Convincing vehicle characteristics and simplified approval procedures

He also praised the driving characteristics of the RBTS. ‘The manoeuvrability of the trailing unit combination is very convincing. The RBTS negotiates bends that cannot be mastered with a telescopic semi-trailer without having to remove crash barriers or carry out widening measures. Some countries would not even allow large-scale modification work. The lift of up to two metres in the free-turning device is also large enough to accommodate obstacles such as surface unevenness and bumps in the road,’ says Adams. These features reduce the time and effort involved in freeing up the route, which is why fewer approvals from the authorities are required. This naturally speeds up the approval process. The plug-and-play system when attaching the rotor blade via the root adapter also functions extremely well. For empty runs, the RBTS can be shortened to form a semi-trailer combination which meets the European standard dimensions of a width of 2.55 metres and a height of less than four metres. At the same time, the empty tractor-trailer combination weighs no more than 40 tonnes. Thus, for example, driving without a load requires less approval procedure.

Prepared for the future thanks to the RBTS from TII SCHEUERLE ‘Without a trailing unit system, fleets that specialise in the transport of rotor blades are no longer future-proof,’ explains the managing director. Because the trend in the industry clearly points to ever more powerful systems with increasingly larger-dimensioned components. With the three RBTS from TII SCHEUERLE, Stephan Adams has optimally equipped his fleet for accommodating the future of wind energy. An achievement that an international expert jury of journalists from 16 European transport magazines recognised through the Trailer Innovation Award at the official launch of the vehicle and for which the RBTS received the title ‘Trailer Innovation 2021’ in the chassis category.